UVLED digital printing industry application

UV printing

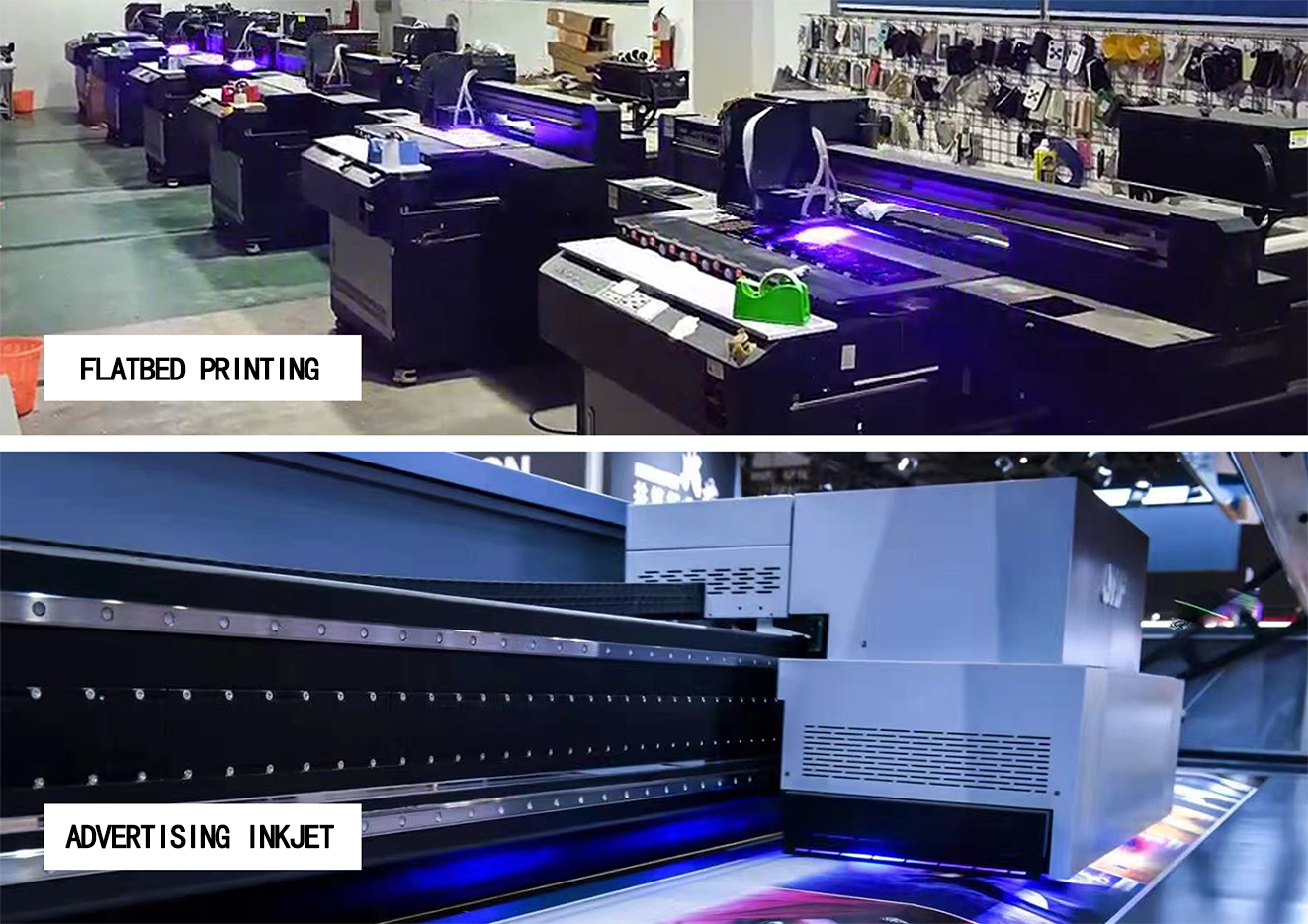

Equipment for printing hard and soft materials

UV printers, also known as universal flatbed printers or flatbed printers, break through the bottleneck of digital printing technology and realize a true one-piece printing, no plate making, and full-color image printing at one time. Compared with traditional printing processes, UV printers have many advantages.

The initial design and manufacture were mainly used for inkjet printing of hard materials. It broke through the limitation that inkjet technology can only print on soft materials. The birth of the domain era.

Printing has been abroad for many years, and it cannot be seen as an addition to the existing wide-format image imaging market, but is positioned as a cheaper alternative to the short-term screen printing market. For large-format images for short-term applications, traditional screen printing requires high costs, while flatbed printer printing is much more economical. In addition, at least 30% of flatbed printers are not used in the traditional image field, but in other unique personalization applications, such as: a British company purchased three UV flatbed printers to print toilet seats for customers.

The UV flatbed printer adopts the latest LED technology, the power is only 80W, energy saving and environmental protection, no preheating, no thermal radiation, no deformation of the printing material, long life of the LED lamp, waterproof and anti-ultraviolet, and extremely low maintenance cost.

1. POP display board

POP display boards are one of the most important applications of wide-format images, including digital inkjet, printing or screen printing, accounting for a total of 42% of the wide-format image market. Using UV ink to directly print on hard boards, such as: KT board, acrylic board, plexiglass board, etc., reduces the trouble of lamination, fading, and foaming, and saves a lot of labor.

2. Hard sign

The production of hard signs is very similar to POP, and it is also a beneficiary of flatbed printers. Flatbed printers using UV ink can directly print on the final sign material, such as metal, wood, plastic, etc. Compared with the traditional method: spraying or printing on the adhesive-backed film material and then pasting it, it not only reduces the process, reduces the cost, but also increases the firmness.

3. Cardboard or corrugated packaging

Another well-established target application area for flatbed printers is packaging, a large industry with an estimated global market of more than $80 billion. Packaging companies that primarily use flexography, screen printing, and stencil printing can purchase flatbed printers for proofing and direct output for low-volume custom customers.

4. Professional market (special products and decoration market)

The last field of application is the professional market, or personalization market. Inkjet toilet lids belong to this market, and other potential opportunities include: glass, ceramics, wood panels, and even furniture. In general: we should first aim at the low-efficiency, low-capacity manual or semi-automatic screen printing market. Flatbed printers are more suitable for small-batch personalized production, while the cost of traditional production is very high, especially if there are A high raw material inventory cost.

If there are thousands of flatbed printers in use worldwide, it is clear that there is a quantifiable and growing market for flatbed printers. In the near future, because the production capacity of the manufacturer cannot meet the market demand, many customers will wait for a long time after placing an order. Based on this optimistic view of the flatbed printer market, flatbed printers will one day be ubiquitous, more popular than inkjet systems.

Environmentally friendly UV ink

Flat-panel inkjet printers use UV ink. As countries pay more attention to environmental protection, there will be stricter market specifications for environmentally friendly equipment and auxiliary media. It is worth mentioning here the advantages of using UV ink, which are characterized by: stable printing, bright colors, high curing strength, low curing energy, environmental protection and no peculiar smell. The multi-applicability and broad application prospects of UV ink provide customers with more development opportunities.

Advantages of cold light source curing lamps for uv flatbed printers.

Advantage:

1. The latest technology focusing reflector is used to concentrate the reflected UV light energy, and the light curing efficiency is high. Dust pollution will affect the printing effect.

2. Select the best mirror-finished aluminum oxide plate, the reflectivity of the UV cold light source reaches more than 90%, which greatly improves the utilization rate of ultraviolet rays and reduces energy consumption; unlike some small modified manufacturers, which are set with steel Iron to deceive customers, not only has a short service life, but also has poor reflection efficiency, resulting in the inability of the ink to dry and solidify.

3. Since the wavelength curing of different inks under ultraviolet light is different, it is necessary to match a special UV lamp. How to ensure the output of the rated full power of the uv lamp has become the top priority. In the selection of the transformer, our company adopts the transformer imported from the EU, which has a long and stable service life, which is more than 3 times that of an ordinary transformer.

4. The design concept of the size and shape of the lampshade is also our patented technology. The light emitted by different power UV lamps is not the same. It is not simply to say that the light is irradiated on the printing material. It involves the utilization rate and conversion rate of ultraviolet rays. The perfect mold shape of the golden ratio makes the ultraviolet rays The loss rate of light is reduced to less than 10%, and the corresponding utilization rate and conversion rate are up to 90%, which ensures the synchronization of ultraviolet frequency and the stability and longevity of ink, allowing you to print and dry immediately. And it's deep, more than 95 percent dry inside.

Troubleshooting

UV flatbed printer solution method:

The blockage of the printheads of UV flatbed printers is almost always caused by the precipitation of impurities, and also partly because the acidity of the ink is too strong, which causes the corrosion of the printheads of the UV flatbed printers. If the ink delivery system is blocked or the print head is blocked because the UV flatbed printer has not been used for a long time or added non-original ink, it is best to clean the print head. If washing with water can not solve the problem, you can only remove the nozzle, soak it in pure water of about 50-60 ℃, clean it with an ultrasonic cleaner, and dry it after cleaning before use.

Analysis 2: The swing speed becomes slower, resulting in low-speed printing

The transformation of the continuous ink supply system often involves the transformation of the original ink cartridges, which will inevitably result in the burden of the word car. In the case of heavy load, the carriage will move slowly. And the heavy load will also lead to accelerated aging of the UV flatbed printer belt and increase the friction between the carriage and the connecting rod. These will cause the UV flatbed printer to slow down. In severe cases, the carriage can not be reset and cannot be used.

Clever solution:

1. Replace the motor.

The hose of the continuous ink supply system rubs against the wall of the UV flatbed printer, resulting in an increase in the load of the electric motor, and the loss of the electric motor after long-term use, try to replace it;

2. Lubricate the connecting rod.

After a long time of use, the friction between the carriage and the connecting rod in the machine becomes larger, and the increase in resistance causes the electric motor to run slowly. At this time, lubricating the connecting rod can solve the fault;

3. The belt is aging.

The friction of the driving gear connected to the motor will increase the aging of the belt of the UV flatbed printer. At this time, cleaning and lubrication can reduce the failure of the belt aging.

Analysis 3: The ink cartridge cannot be recognized

Users who use continuous ink supply may often encounter such a situation: the machine does not print after a period of use, because the UV flatbed printer cannot recognize the black ink cartridge.

How to solve the UV flatbed printer:

This happens mainly because the waste ink tank of the UV flatbed printer is full. Virtually every UV flatbed printer has a fixed accessory life setting. When some accessories reach the service life, the UV flatbed printer will prompt that it cannot print. Since waste ink is easily formed during the use of the continuous ink supply system, it is easy to cause the waste ink tank to be full. There are two ways to deal with this situation: or use the reset software to reset the UV flatbed printer motherboard to eliminate the settings of the UV flatbed printer; or you can go to the maintenance point to remove the sponge in the waste ink tank. replace. Twinkle recommends that users adopt the latter. Because just a simple reset can easily lead to waste ink missing and burning the UV flatbed printer.

In addition, the failure of the cleaning pump nozzle of the UV flatbed printer is also the main reason for the blockage. The cleaning pump nozzle of the UV flatbed printer plays a decisive role in the protection of the printer nozzle. After the carriage returns to its position, the nozzle should be cleaned by the pump nozzle for weak air extraction, and the nozzle should be sealed and protected. When a new ink cartridge is installed in the UV flatbed printer or the nozzle is disconnected, the suction pump at the lower end of the machine should use it to pump the nozzle. The higher the working accuracy of the suction pump, the better. However, in actual operation, the performance and air tightness of the suction pump will be reduced due to the prolongation of time, the increase of dust and residual coagulation of ink in the nozzle. If the user does not check or clean it frequently, it will cause the nozzle of the UV flatbed printer to continue to have similar plugging failures. Therefore, it is necessary to maintain the suction pump frequently.

The specific method is to remove the upper cover of the UV flatbed printer and remove it from the trolley, and use a needle to inhale pure water to rinse it, especially to fully clean the microporous gasket embedded in the mouth. It should be noted that when cleaning this component, it must not be cleaned with ethanol or methanol, which will cause the microporous gasket embedded in this component to dissolve and deform. At the same time, the lubricating oil should not be in contact with the pump nozzle. The grease will deform the rubber sealing ring of the pump nozzle and cannot seal and protect the nozzle.

maintainance

1. Ensure that the environment around the UV flatbed printer is clean. Too much dust in the working environment will easily lead to poor lubrication of the guide shaft of the trolley, which will hinder the movement of the print head during the printing process, causing inaccurate printing position or hitting the mechanical frame, causing damage and crash. When the print head is restarted without returning to the original position, the printer will first return the print head to the original position, and then clean the nozzle, which will cause unnecessary waste of ink. The solution to this problem is to often wipe off the dust on the guide shaft and lubricate the guide shaft (use lubricating oil with better fluidity, such as sewing machine oil).

2. It must be ensured that the UV flatbed printer has a stable working platform, and do not place any items on the top of the UV flatbed printer. The front cover of the printer must be closed when printing to prevent dust from entering the machine or other hard objects hindering the movement of the printer carriage. It is forbidden to plug and unplug the printer cable under power, which will damage the printer's print port and the PC's parallel port, and even damage the PC's motherboard in serious cases. If the printout is not very clear, you can use the printer's automatic cleaning function to clean the nozzle, but it will consume a small amount of ink. If the printing is still unsatisfactory after several consecutive cleanings, the ink may be used up and the ink cartridge needs to be replaced.

3. Before turning off the machine, let the print head return to the initial position (when the printer is in a pause state, the print head automatically returns to the initial position). One is to avoid wasting ink when the printer is re-cleaning the nozzles when the printer is turned on next time, and the other is that the nozzles can be sealed by the protective cover at the initial position, so that the nozzles are not easily blocked.

4. Ink cartridges need to be calibrated frequently: users who have experience in using printers know that the printer needs to be calibrated after the ink cartridges are reinstalled or replaced with new ink cartridges to improve printing accuracy and print quality.

5. When the ink cartridge is not used up, it is best not to remove it, so as to avoid waste of ink or wrong measurement of ink by the printer.

6. When the ink cartridge is not used for a long time, it should be placed at room temperature to avoid direct sunlight. Because the ink evaporates quickly in this environment, it is easy to cause the nozzle to block. In addition, in a low temperature and humid environment, the print head circuit and ink are prone to problems.

7. When replacing the ink cartridge, be sure to follow the steps in the operation manual, and pay special attention to the above operations when the power is turned on. Because after the ink cartridge is replaced, the printer will charge the ink delivery system, and this process will not be possible in the off state, and the printer will not be able to detect the reinstalled ink cartridge. In addition, some printers measure the ink volume by using the electronic counter inside the printer (especially in the statistics of color ink usage). When the counter reaches a certain value, the printer judges that the ink is exhausted. During the ink cartridge replacement process, the printer will reset its internal electronic counter to confirm that a new ink cartridge is installed.

8. In addition, the grating strip of the uv flatbed printer should also be well protected, do not touch it with your hands, and do not let it be contaminated with dust to prevent inaccurate positioning.

Nozzle cleaning

Preparations: The rear compartment where the print head nozzle of the universal printer is located also includes the nozzle drive circuit board, so it is necessary to do a good job of protecting the drive circuit board, and wrap the rear half of the compartment with the usual plastic wrap.

Step 1: Soak

Prepare a small flat plate, place the nozzle flat on the plate, and then pour the special cleaning solution for universal printers into the plate. Be careful not to splash water on the cable plug and drive circuit board, the first soaking time is about an hour.

Step 2: Cleaning

1. Use a damp cloth to gently absorb the water stains of the nozzle, do not wipe the nozzle at the bottom of the nozzle.

2. Repeat the process for all heads to be cleaned. A clean area of the cloth should be used for each sprinkler.

3. If the nozzle is blocked, you can heat the distilled water a little and put a small amount on the plate. When placing the sprinkler on the plate, the water level should not be higher than 2CM from the bottom as water may leak behind the chip.

4. Put the nozzle upright in warm water. Wait 30 seconds, blot the nozzle dry before testing.

5. Each nozzle should be cleaned with clean water. (The nozzle can also be cleaned with an ultrasonic cleaner)